Such crowns are either pre manufactured delivered to the building site or created on site by pouring concrete directly on top of the chimney into the assembled form this method is called cast in place.

Chimney crown cement mix.

Most concrete mixes i think run between 3 000 4 000 psi but i do not know what mortar mixes are designed for.

Fill the form half full with concrete.

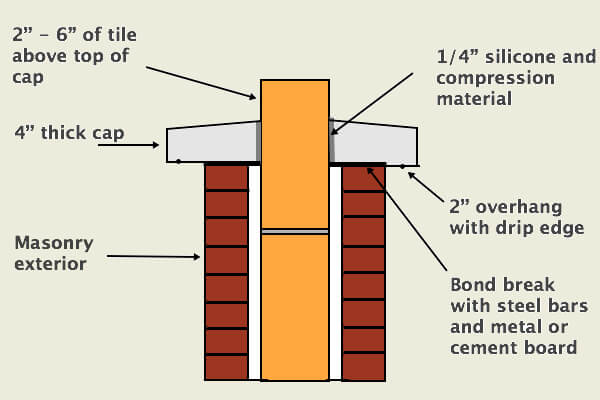

The thinnest part of precast concrete crowns must be at least 2 inches.

This serves two purposes.

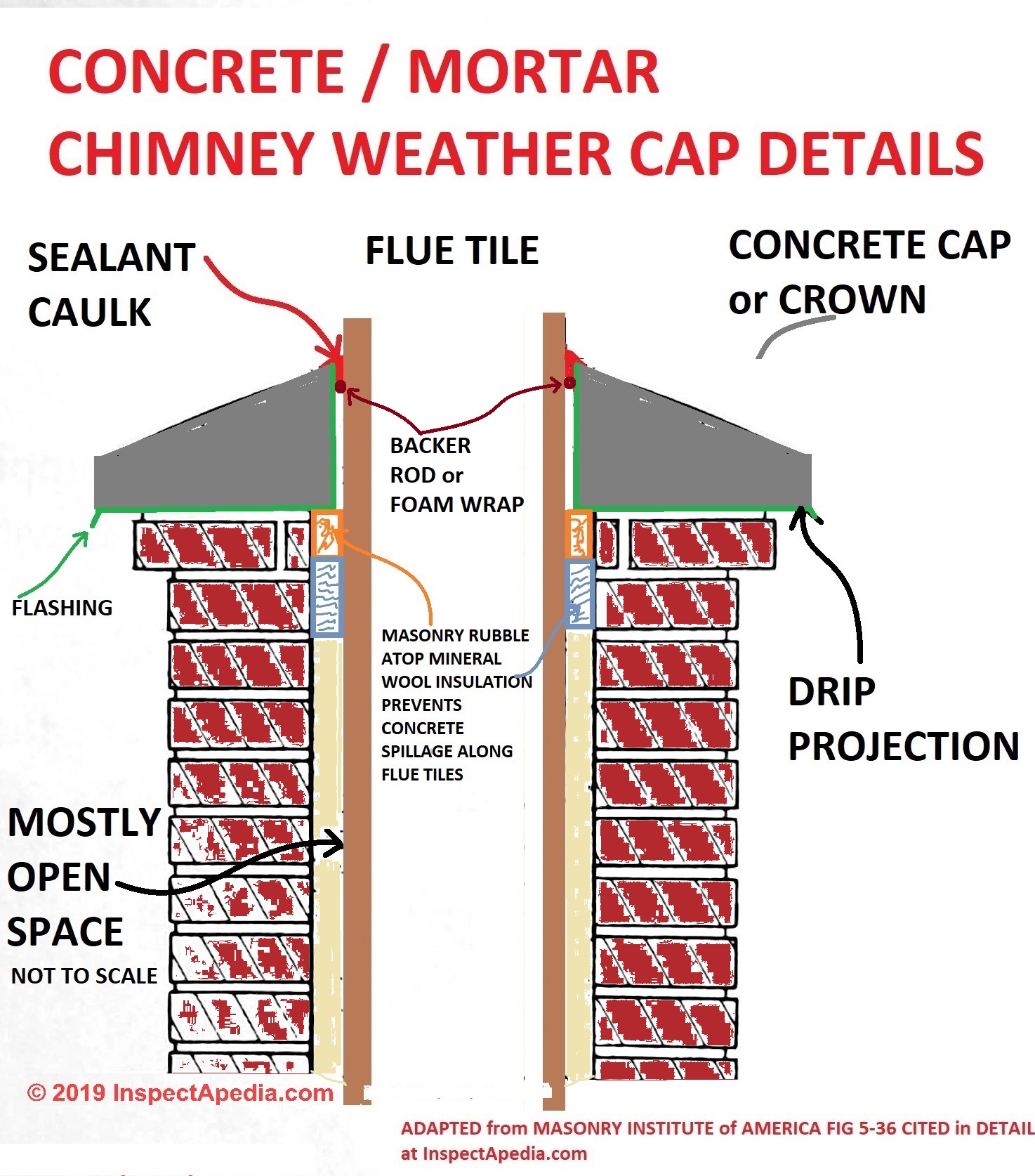

First without the barrier the cement will just run down the chimney structure filling the airspace between the flue and the masonry walls.

I show you all the steps i used chipping out the old crown cutting plywood if you are worried about moisture use 1 2 hardie bac.

Combine dry concrete mix water and light aggregate such as gravel or crushed rock.

The crown should be made of concrete only and mortar should not be used.

The stones in concrete are what really give it its strength.

Then carry the wet concrete up to the roof in buckets small enough that you can carry them.

And if an air entrainment agent is added it will have added resistance to weather deterioration.

If the chimney has clay flue liners the crown or top concrete material should never touch the flue liners.

Chimney crowns cement chimney crown repair while the very top of your chimney may fall into the category of things that are out of sight and out of mind this oversight could be detrimental to the condition of your chimney.

Diy chimney crown repair.

The chimney crown should be made using real concrete not the mortar mix used for the brick or stone.

The chimney crown should extend up to a minimum of 2 5 inches beyond the chimney wall and a drip edge should be provided at the bottom of the overhang part of chimney crown.

The mortar mix rarely has any stones in it.

A brick chimney crown made out of concrete should be at least 2 thick and have a 2 1 2 overhang recommended by the brick institute of america to protect the face of the brick wall it sits on.

Then lay sheet metal or cement board across the metal supports to form a thin bond break between the chimney crown and the masonry walls.

Portland cement to bond water to turn it into a paste sand and hydrated lime to strengthen the mix are added to the product.

However the types are differentiated due to the different proportion of ingredients added.

Type o is the least strong of all the mortar types and is suitable for lightweight jobs and tiny chimneys.